SERVICES

PRODUCT ENGINEERING

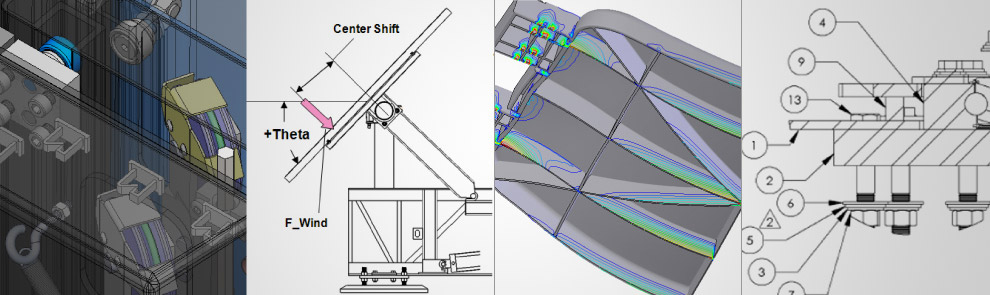

The Raytech product engineering team provides mechanical design, stress analysis, design for manufacturability, and material selection services using advanced software run by experts in Finite Element Analysis (FEA), Computational Flow Dynamics (CFD), manufacturability and Mold Flow Analysis.

The Raytech product engineering team provides mechanical design, stress analysis, design for manufacturability, and material selection services using advanced software run by experts in Finite Element Analysis (FEA), Computational Flow Dynamics (CFD), manufacturability and Mold Flow Analysis.

Raytech’s engineers evaluate product functionality, structural integrity, wear resistance, and manufacturability. The depth of our professional engineering experience and software capabilities enables our engineers to adapt to unique project requirements.

Our product engineering group’s extensive experience in manufacturing processes includes plastic injection molding, thermoforming, plastic and aluminum extrusion, machining, metal stamping, metal casting, drawing, four-slide and other manufacturing processes.

Key Strengths:

- Mechanical Design

- Engineering for Manufacturability

- FEA for Structural & Thermal Analysis

- Value Engineering

- Material and Process Selection

- Mold Flow Analysis

MOLD FLOW ANALYSIS

Combining dozens of years of molding experience with injection molding simulation and analysis tools, Raytech’s plastics engineering team analyzes parts designed to be injection molded to help select and specify materials and mold tooling and press parameters in order to... read more

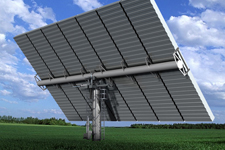

MECHANICAL ENGINEERING

Raytech’s engineers design parts and mechanisms for smooth functionality and mechanical strength, and for manufacturability. From the smallest consumer devices to public utility size solar installations, Raytech's engineers have the training and experience to handle.... read more

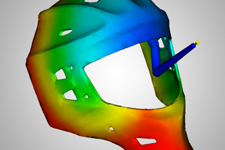

FINITE ELEMENT ANALYSIS

Raytech’s analysis team uses FEA to assist with mechanical development and material choice. Raytech engineers use computer models to predict the stresses and deflections of a product during normal usage and under extreme conditions. Raytech engineers provide structural analysis... read more

STRUCTURAL ENGINEERING

Raytech’s mechanical engineers provide structural engineering expertise for large mechanisms and structures. Creative design and careful analysis are used to develop efficient, safe and durable equipment. Using a combination of standard engineering calculations and computer... read more

DESIGN FOR MANUFACTURING

Design for manufacturability is the meat of the design process. Raytech’s industrial designers and engineers work together to develop products that meet industrial design, mechanical, and manufacturability requirements. At Raytech, we design the manufacturing process... read more

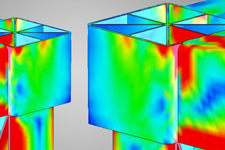

COMPUTATIONAL FLOW DYNAMICS