SERVICES

ENGINEERING > MOLD FLOW ANALYSIS

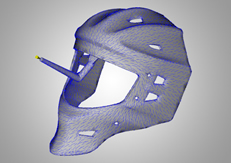

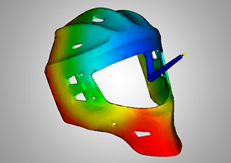

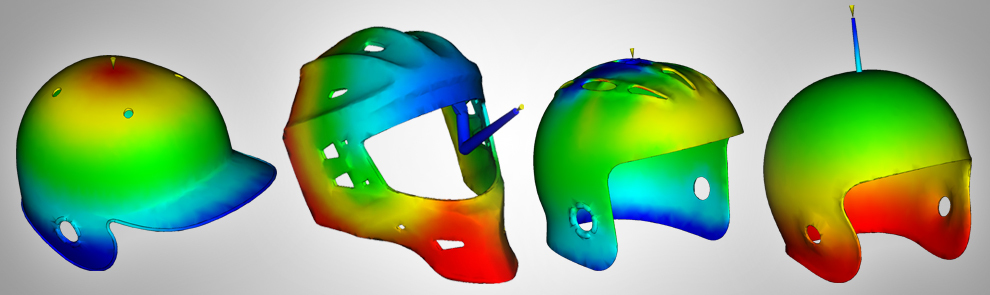

Combining dozens of years of molding experience with injection molding simulation and analysis tools, Raytech’s plastics engineering team analyzes parts designed to be injection molded to help select and specify materials and mold tooling and press parameters in order to optimize cycle time, part fill, strength and cosmetic appearance.

• Gate size and location

Combining dozens of years of molding experience with injection molding simulation and analysis tools, Raytech’s plastics engineering team analyzes parts designed to be injection molded to help select and specify materials and mold tooling and press parameters in order to optimize cycle time, part fill, strength and cosmetic appearance.

Whether for an existing part currently in production or while preparing to build a new mold, Raytech's engineering staff optimizes part integrity, and manufacturing costs by providing specific molding parameters including:

• Gate size and location

• Back Pressure

• Venting Requirements

• Weld line minimization and placement

• Sink marks

• Part strength

• Warping

• Injection Speed and Pressure

• Pack Pressure

• Cooling

• Nozzle Size

• Injection cycle time